How Offset Lithography Works

Offset lithography — also known as offset printing, offset or simply litho for short — is the most commonly used printing method today. In offset lithography, an inked image is transferred (offset!) from a metal printing plate (originally stone, hence the term “litho”) to a rubber blanket and then onto paper or some other substrate. All offset lithography presses basically work the same way, whether they are a sheet-fed press or a web press running a huge roll or “web” of paper.

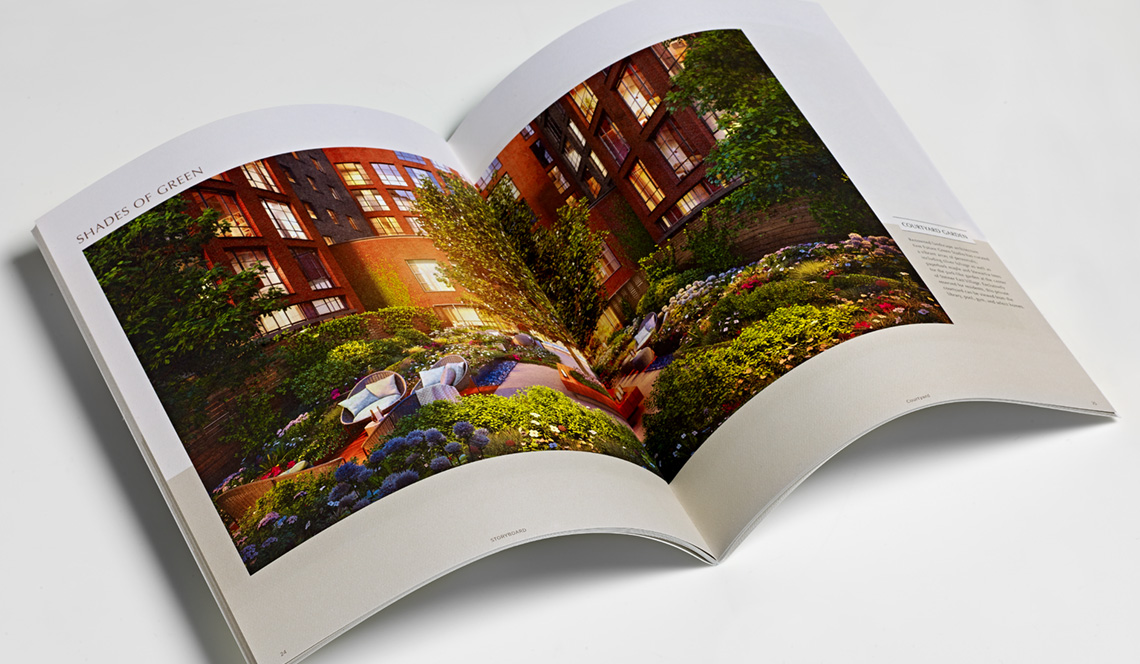

Because the ink from the image to be printed is first transferred to a rubber plate, offset lithography can be used to print an image or design onto a variety of substrates that other types of printing can’t accommodate. These include metal, wood, plastic and fabric. Near photographic quality can be achieved using fine line screens, which convert continuous tone images into barely perceptible patterns for each color that is to be offset printed. You would practically need a magnifying glass to see the line screen of photographs printed onto some finer coated papers!

Inks

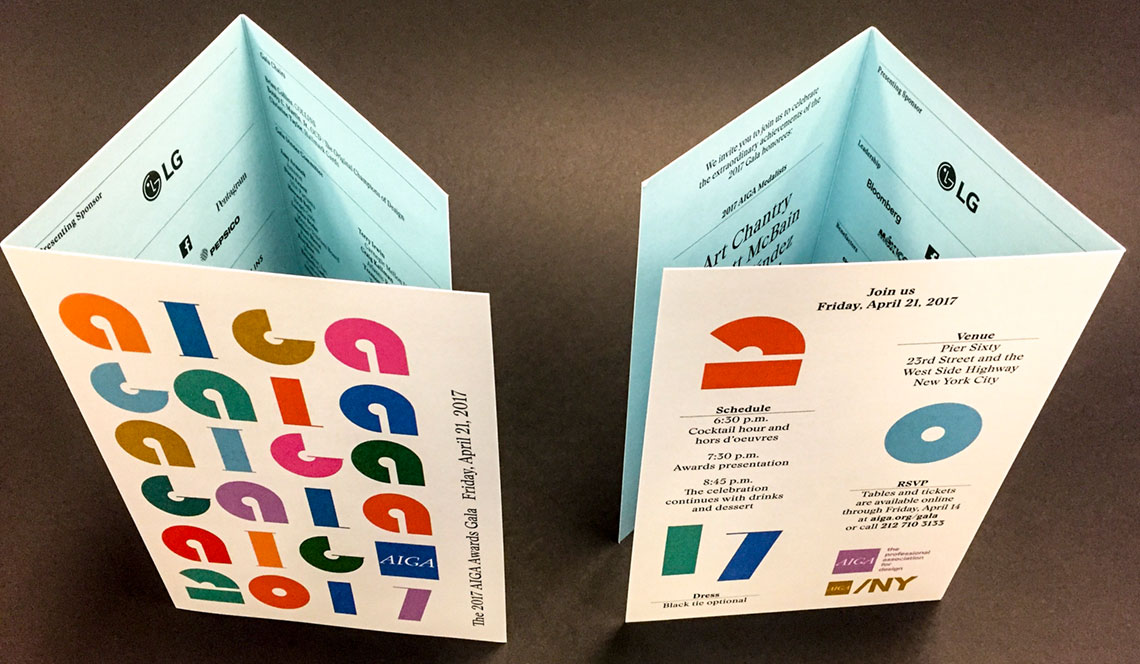

Offset lithography inks sit flatly on the surface of the paper or substrate, which is why some people refer to offset lithography as flat printing. As such, it is not tactile in the way that engraving, embossing/debossing, and letterpress are. Ink color options are almost infinite and our ink labs achieve great color consistency including custom PMS/Pantone color matches. We can even create unusual effects by layering and overprinting inks.

Depending on the substrate, offset printing inks can be relatively transparent. Our master printers will sometimes recommend adjusting the formula to take into account the paper color and printing surface in order to achieve our clients’ desired outcomes.

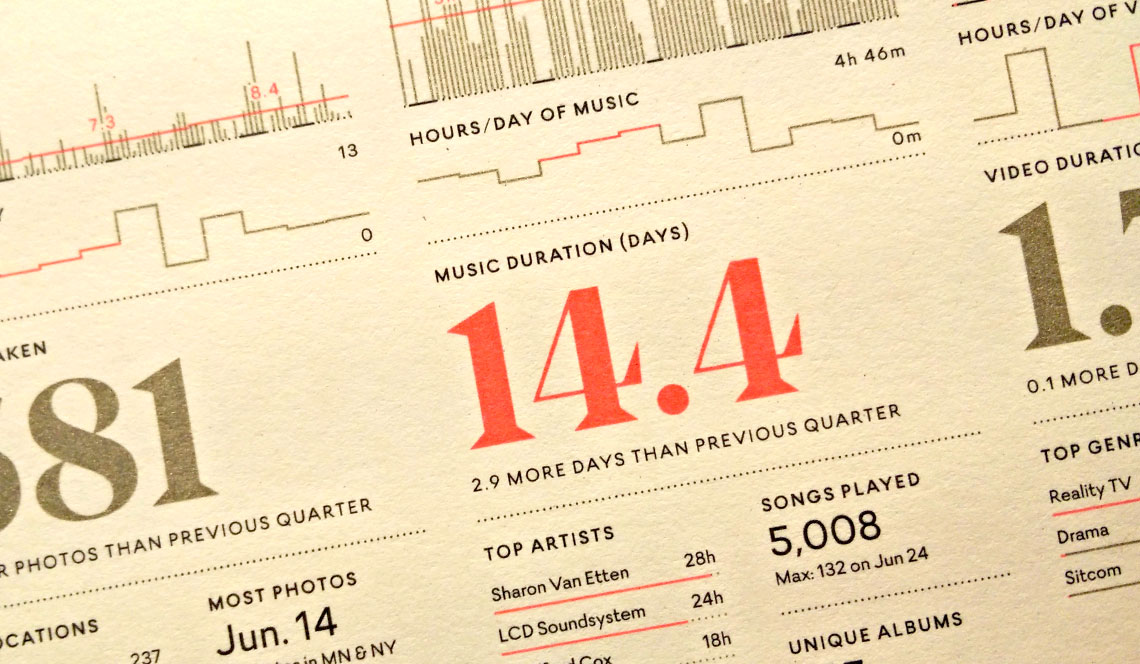

Individual colors can be printed as separate plates and will be as vibrant as any color that can be mixed, including florescent hues. In 4-color offset lithography, all of the combined colors of a design – including the typography, photography and other design elements – are separated into four separate plates: cyan (C), magenta (M), yellow (Y), and black (B). These colors, referred to as CMYK, represent the backbone of all full-color printing and, when combined using different line screens, can reproduce most colors reliably.

Some of our clients request that we match their brand colors on a piece that also contains full-color images such as photographs. In these cases, we will print CMYK plus any additional PMS colors onto the same sheets creating 5, 6, 7-color or more prints!

Additionally, metallic inks can be used to achieve similar effects as foil stamping without the costs of an additional printing process. Golds and silvers are just the beginning as ink manufacturers have created tints of these in several different hues.

Why We Love Offset Lithography

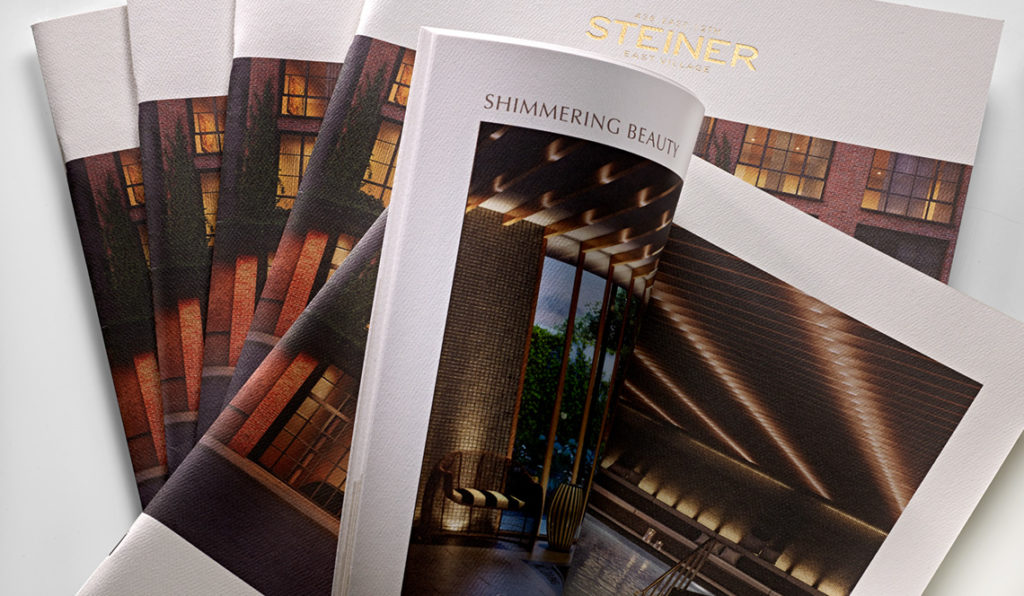

Offset lithography can be combined with the other tactile specialty printing processes we offer in-house to create rich detail and intriguing effects. We also love how offset printing can reproduce photography with incredible fidelity and color matching.

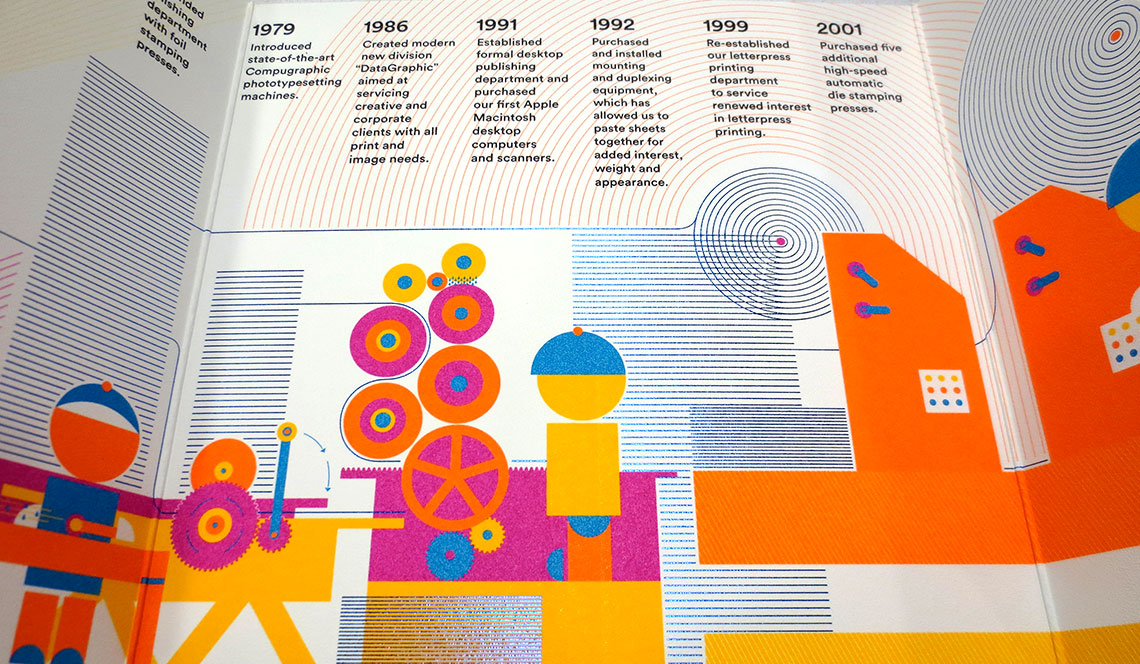

Since its emergence in the 1950s, the offset printing process has taken major leaps forward. We now utilize “direct-to-plate” technology, side-stepping the need to create films for each color prior to exposing the plates. This removes one complete “generation” from the imaging process and results in better overall quality and quicker turn-around times for our clients. Optional coatings such as aqueous, film laminations and UV inks enable us to achieve impeccable results on every-day jobs.

Overall, we think offset lithography or offset printing can be a cost-effective was to achieve very high-quality printing on a variety of surfaces. And, when combined with finer processes like engraving and embossing, the results can be over-the-top.